According to Price Water Cooper, Nigeria is currently the second largest producer of fresh tomatoes in Africa. Despite the vastness of this industry, the production of fresh tomatoes in Nigeria is still growing at a rate of about 25% over the last decade1.

Tomato Production Rate

Despite the vastness of this industry, the production of fresh tomatoes in Nigeria is still growing at a rate of about 25% over the last decade1. This very important food is consumed by all demographics in Nigeria; the rich, the poor, old, and young always have tomatoes consumed either at home, at eateries or at parties. Hence, the local tomato market in Nigeria is huge and thriving, where cool cash can be made2.

Why Fruits Rotten?

The reason why fruits become palatable is because they become ripe, becoming soft, sweeter and changing color. This process is necessary for the fruit to become palatable for the consumer, however, the same process is responsible for huge loss of most vegetables or fruits after harvesting or even before picking them away from the field after reaching the maturity stage.

Hence, any strategy that is put in place to slow down the ripening process of your harvest (vegetables or fruits), will ensure that the produce is palatable with reduced amount of loss due to over ripening and spoilage, which reduces the value of the crop. The more the fruit over-ripens the less palatable it becomes for consumption and the lesser the market value of the produce.

To manipulate this process in the harvest, it is necessary to understand the process of ripening itself. Two things are mainly responsible for ripening; respiration and ethylene production. Both of them go hand in hand, so, if you can manipulate the respiration rate then you would have indirectly manipulated the ethylene production rate too.

This article focuses on the fruits that continue to ripen after harvest, and tomato will be used as a case study. The higher the rate of ethylene production the more the food stored in the fruit is used up and the faster the fruit will spoil and reduce in its market value. You will notice that bruised fruit or the one that is cut even slightly will spoil faster than the one that is not bruised or cut open.

This is because the open part of the fruit causes more ethylene to be produced, thus, hastening the ripening and spoilage of the fruit. Another factor that increases the ethylene production rate is temperature, the higher the temperature of the environment of the fruit the more the ethylene production rate and the faster the spoilage. Therefore, to reduce post-harvest loss of your fruit/vegetables you need to reduce the production rate of ethylene in your harvested produce6.

Reducing Tomato Post-Harvest Losses

Many strategies exist to reduce post-harvest losses globally, however, because of the lack of access to sufficient funds by farmers in poor communities, more research is conducted to see how to deploy low cost available resources to reduce post-harvest losses among smallholder and medium scale farmers. According to Prof. Jane Ambuko of the University of Nairobi, cold storage seems to be the best solution so far to the preservation and extension of shelf life sensitive produce like tomatoes7.

Proper handling and packaging prevents bruising of the fruits and cold room storage extends the shelf life. Two main technologies that help reduce the ambient temperature of the storage room of the fruit are: the Coolbot technology and the Zero Energy Brick Cooler.

Cool Storage Procedure for Tomato

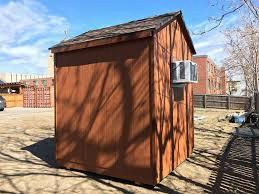

The coolbot technology can best be suited for medium scale farmers because it involves the building of modified cold rooms. With the use of a wall-fitted air-conditioning system and a coolbot temperature regulator, a low-cost, modified cold room is set up for the storage of harvested fruits. The major costs associated with setting up this kind of storage are the expenses on air-conditioner, the coolbot device itself, the room/building and the supply of electricity to power it.

This is a technology that can help medium scale farmers to increase the shelf life of their tomatoes, with proper storage and allow them to make maximum profit on the fresh fruit produce without rushing to sell off the produce because of the fear of deterioration and reduction in market value. If this technology came by research and development, the solution it offers can also be improved by the same process. Therefore, if you are convinced that this solution can be useful for you by improving the shelf life of your vegetables and earn you more income, contact us for more information.

The second technology (Zero Energy Cooler Brick) also depends on reducing the ambient temperature of the storage environment of the produce. However, it is cheaper but not as effective as the coolbot technology. This is best applicable to smallholder or rural farmers who do not have much money to afford the coolbot technology. It involves the use of bricks or blocks, sand, some pipes, tank, water source and a shed, which is relatively cheap to build, and can be used to extend the shelf life of their produce. You can also contact us for more information about this.

Prospect of Profitable Tomato Farming

n conclusion, in the midst of the challenges that face vegetable production, tomato inclusive, it is obvious that there is a huge market and it is a commonly consumed food in all parts of Nigeria. However, to have a robust tomato enterprise that consistently supplies fresh tomatoes and other vegetables, it is necessary to plan on how to reduce postharvest losses after scaling the hurdles of pest and disease on the field. This gives you as a farmer a bit of control on the time of sale of the produce and ability to attract a good market value. If this article really inspires you and you need more information, you can contact us.

REFERENCES

- Price Water Cooper (2018) – X-raying the Nigerian tomato industry Focus on reducing tomato wastage. https://www.pwc.com/ng/en/assets/pdf/nigeria-tomato-industry.pdf

- https://www.agriculturenigeria.com/manuals/production/crop-production/horticulture/tomato/

- Inzlicht, M., Shenhav, A., & Olivola, C. Y. (2018). The Effort Paradox: Effort Is Both Costly and Valued. Trends in cognitive sciences, 22(4), 337–349. https://doi.org/10.1016/j.tics.2018.01.007

- https://croplife.org/wp-content/uploads/pdf_files/Feeding-Nine-Billion-The-Issues-Facing-Global-Agriculture.pdf

- https://en.wikipedia.org/wiki/Ripening

- The University of Maine – Harvest and Storage of Maine Fruits. https://extension.umaine.edu/fruit/harvest-and-storage-of-tree-fruits/the-role-of-ethylene-in-fruit ripening/#:~:text=Methods%20of%20controlling%20ethylene%20in,and%20ethylene%20scubbing%20or%20removal.

Thank you for the article, it’s quite educative and eye-opening. I want to ask the extent to which refrigerator or freezer can aid in preventing post-harvest losses in fruits and vegetables, most especially tomato

Hello Responder,

The Coolbot technology is an aspect of storage which we recommend to be combined with other methods to extend the shelf life of produce.

If the Coolbot technology is combined with a Modified atmosphere packaging, the shelf life of tomato can be extended beyond 21 days.

Attached to this mail is a Tedex video by the leading researcher implementing the Coolbot technology in Kenya and also the research work where you can see some of the storage method that can be combined together.

http://erepository.uonbi.ac.ke/bitstream/handle/11295/99562/KARITHI%20ESTHER%20THESIS%20Final.pdf?sequence=1&isAllowed=y

https://www.youtube.com/watch?v=z3qjxc4_fNA